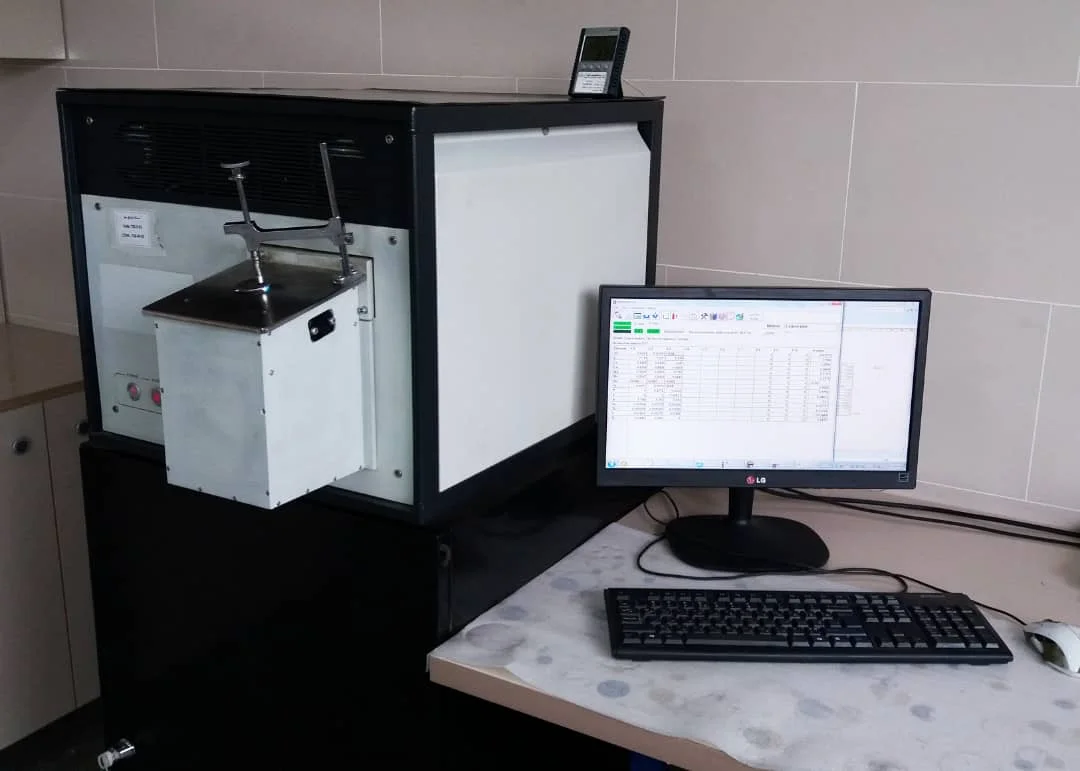

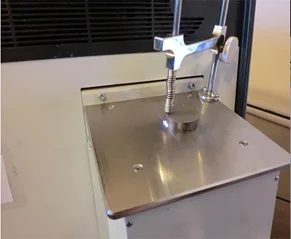

OES (METAL ANALYSIS)

This departman of the laboratory is a main pillar in the path of identifying metal materials using OES technology and relying on experienced experts, which provides the possibility of determining the chemical composition of metals and their compliance with standards.

Multiple standard samples for permanent equipment calibration

Using specialized and experienced experts to track and identify metal materials

In general, the metal materials tested in this laboratory are as follows :

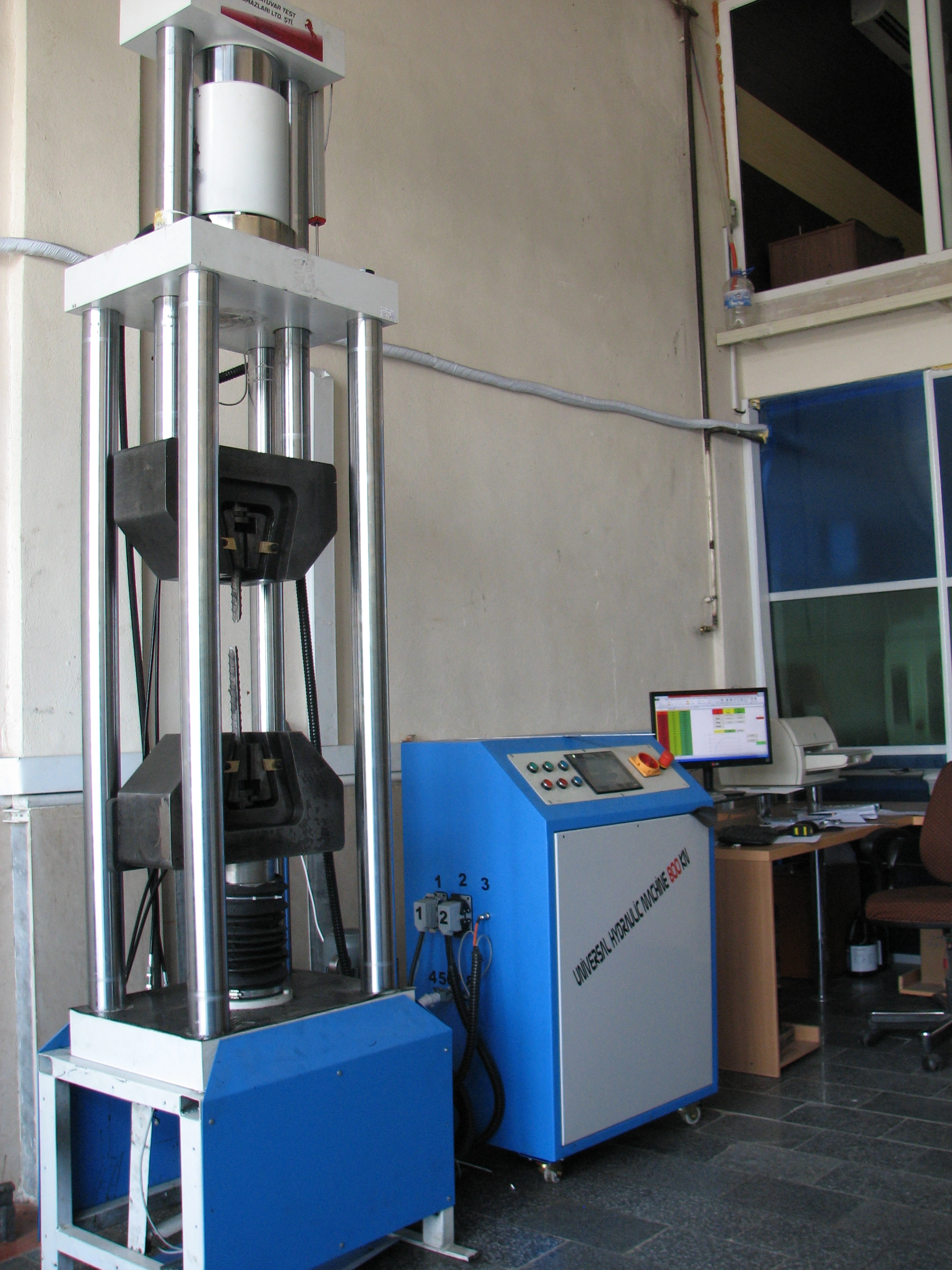

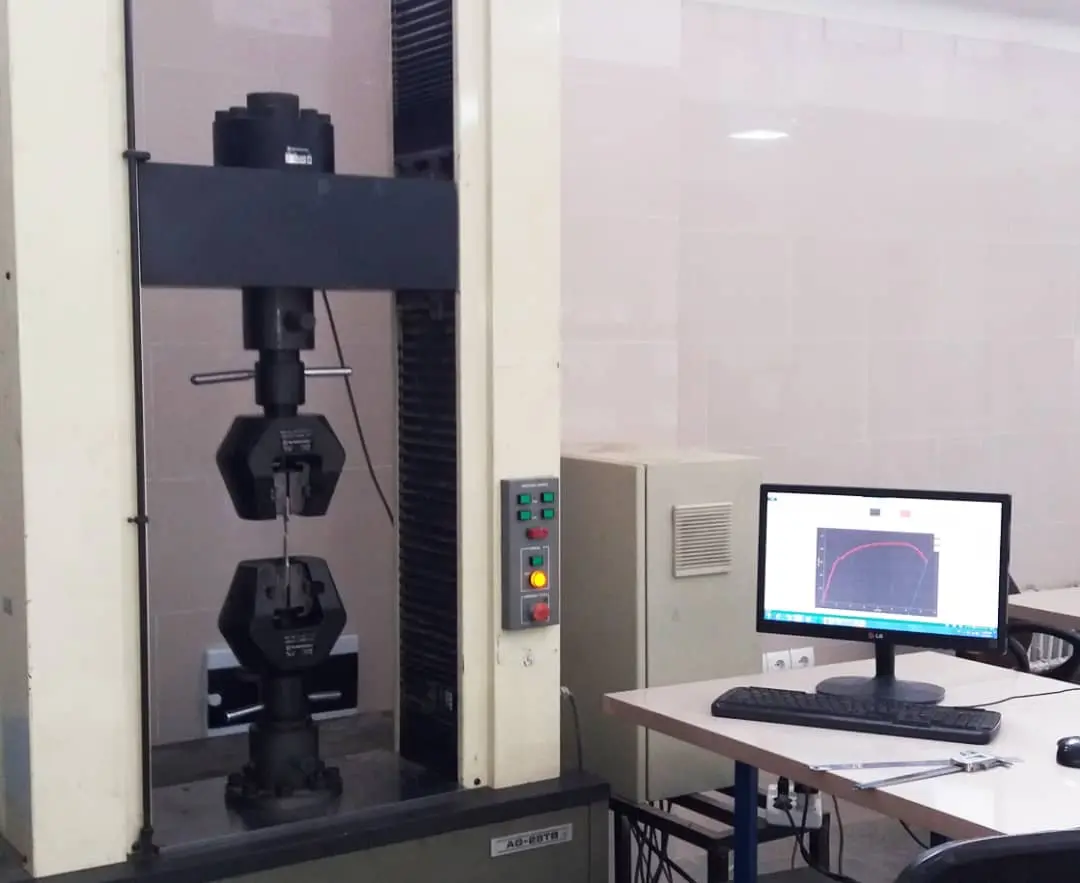

Mechanical properties of materials

This department performs general tests of mechanical properties, including tension, pressure, impact, bending and hardness testing, and specific tests that are defined based on different standards.

Services that can be provided in the mechanical properties laboratory :

Hardness Testing

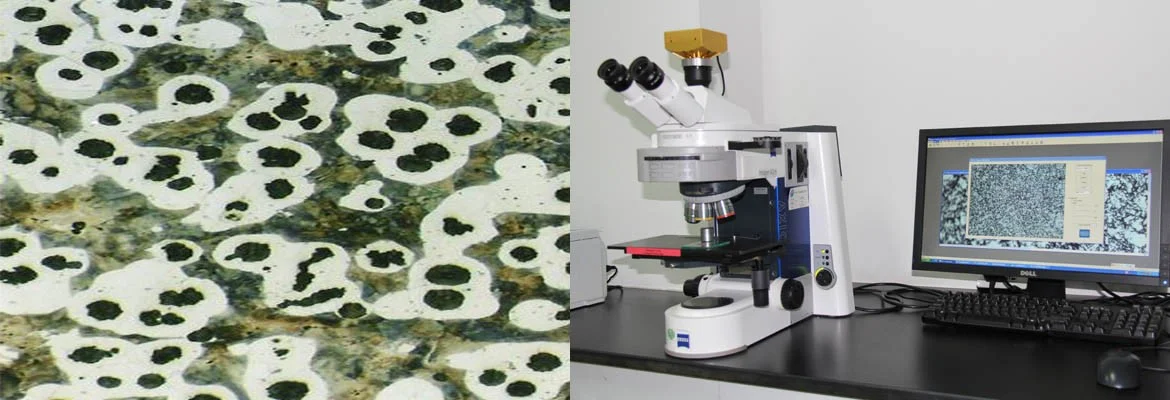

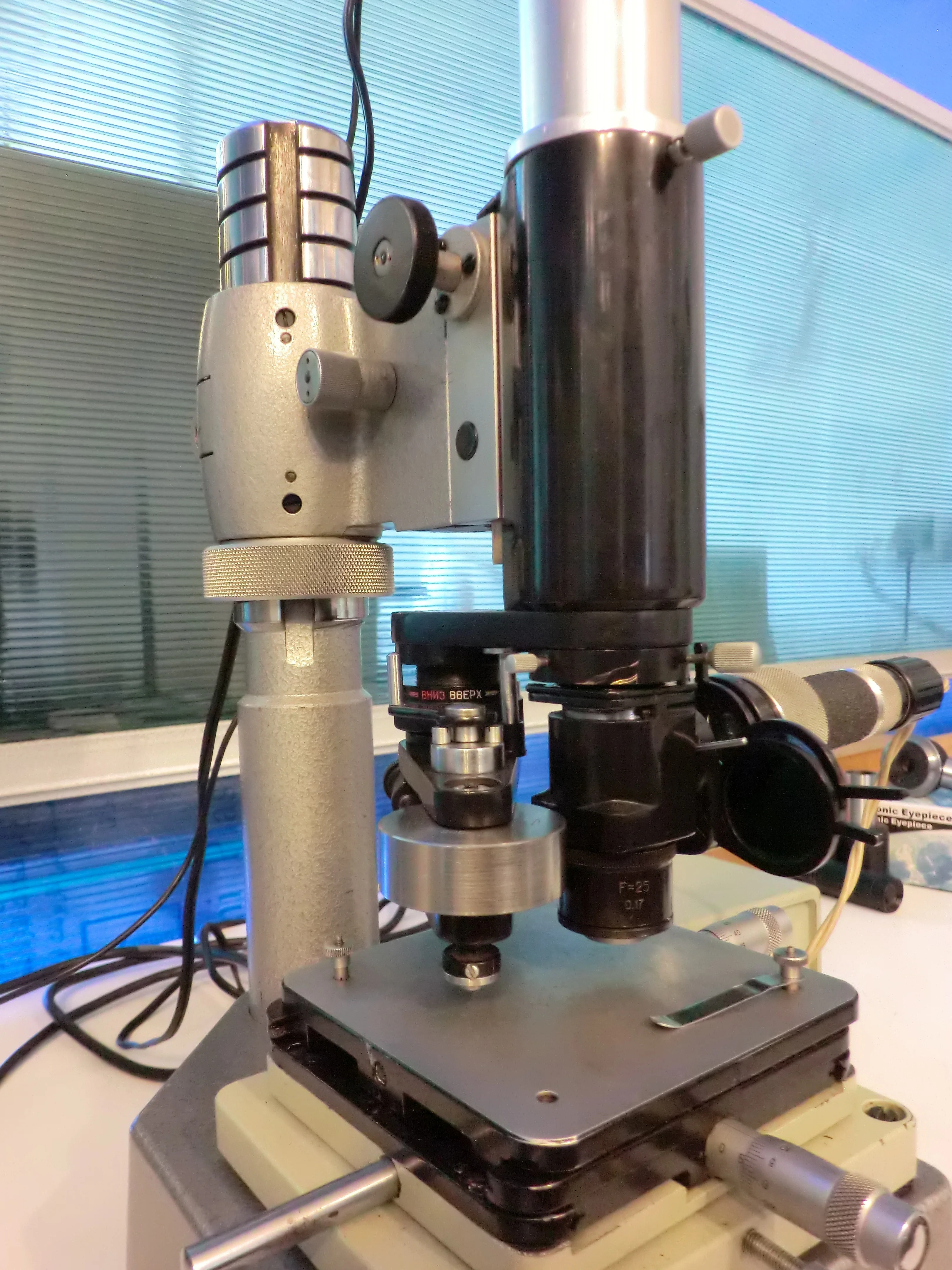

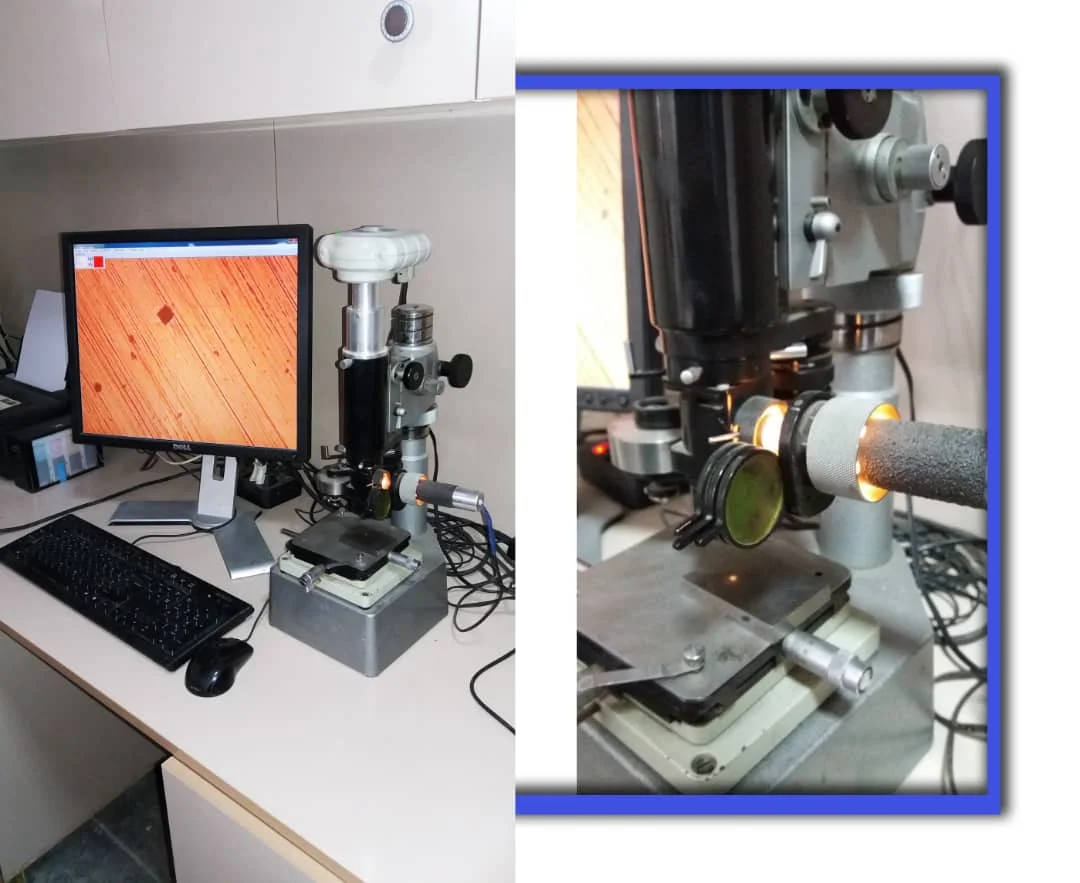

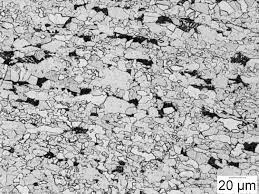

Hardness measurement is a fast method for determining the mechanical properties of parts due to the quickness of the test and the need for light preparation. Also, the hardness value can be used to determine the macrostructure and microstructure of the parts. This test method can be done without destroying the sample. Hardness measurement is used for wide categories of metals and non-metals due to the variety of scales and applied forces. Also, hardness measurement is a reference method for determining the accuracy of heat treatment applied on parts.

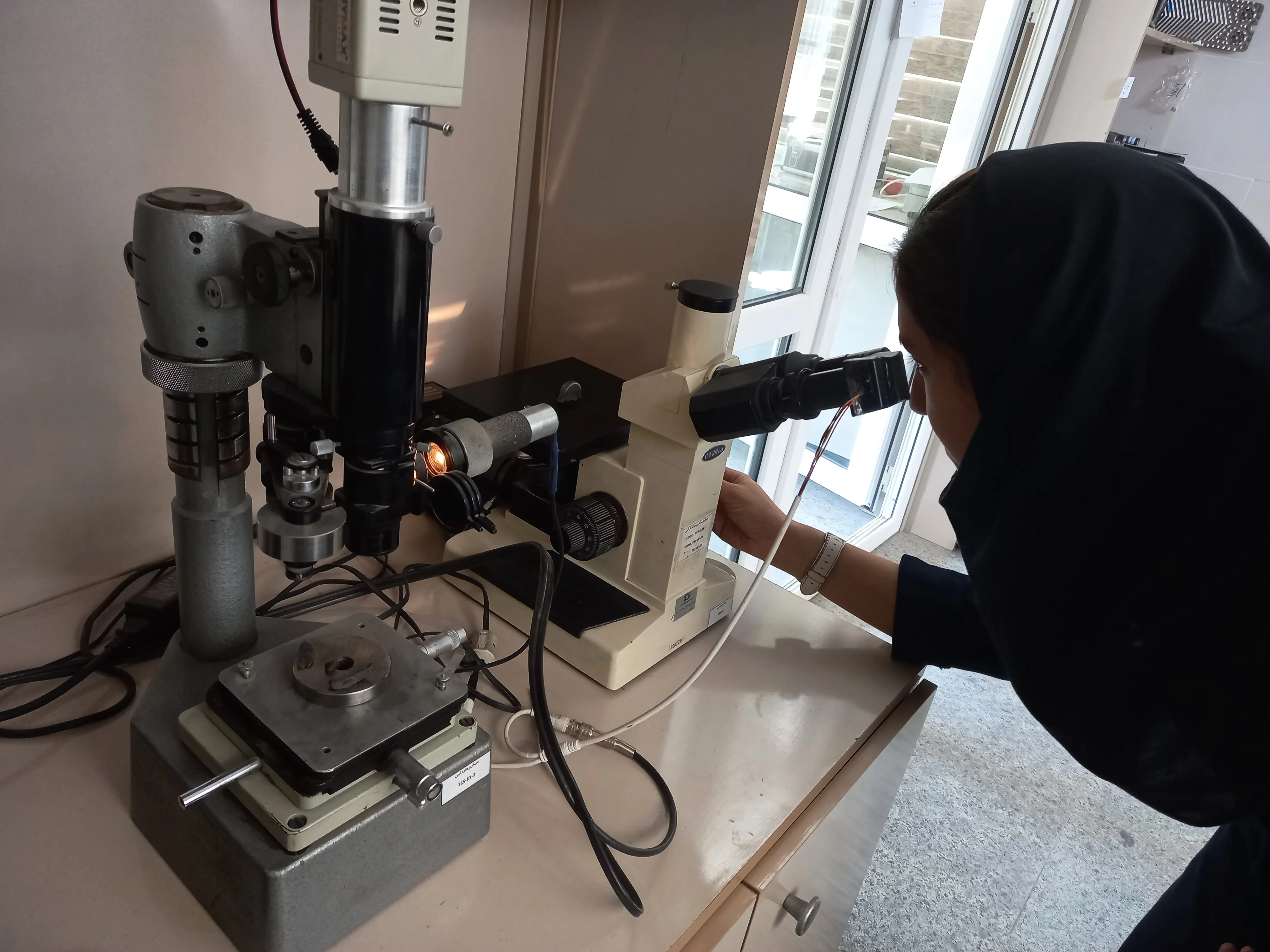

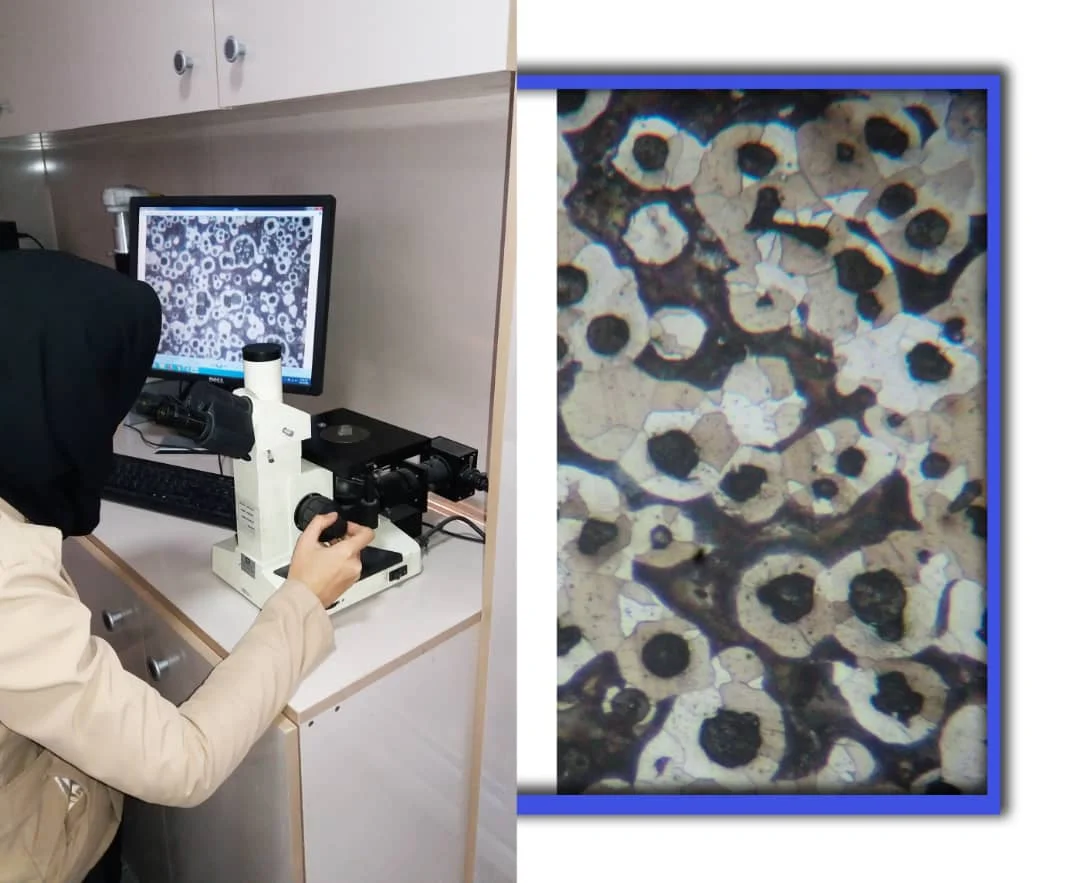

Metallography

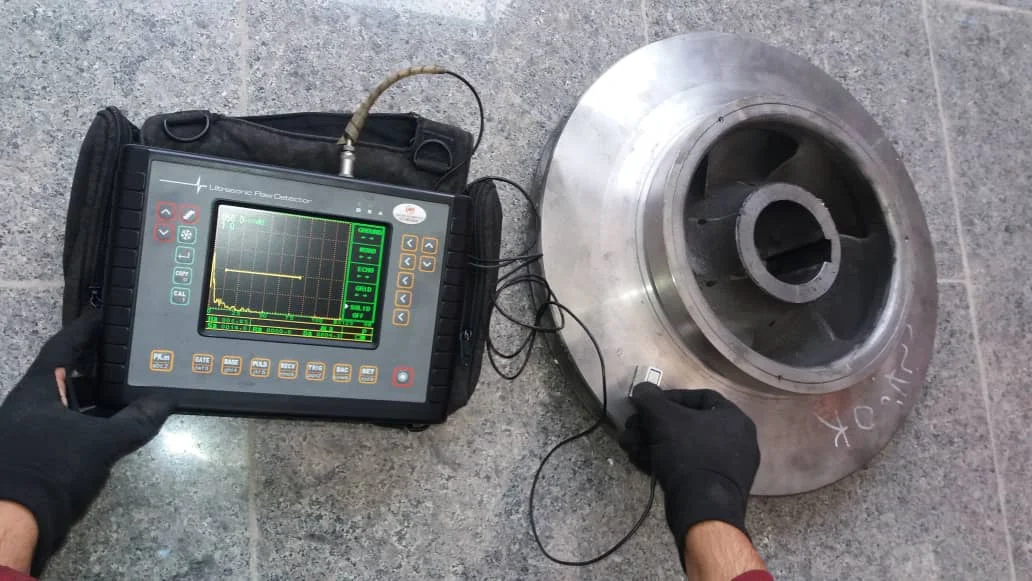

NON Destructive Test

Weld Engineering

WELDING PROCEDURE SPECIFICATION - WPS

PROCEDURE QUALIFICATION REPORT – PQR

WELDER QUALIFICATION TESTING – WQT

Corrosion and Insulation

NACE TM 0177

Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments

NACE MR 0103

Metallic materials resistant to sulfide stresscracking in corrosive petroleum refining environments

NACE TM 0284

Evaluation of Pipeline and Pressure Vessel Steels for Resistance to Hydrogen-Induced Cracking

NACE MR 0175

Materials for use in H2S-containing environments in oil and gas production

ASTM A 262

Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

Portable Testing

Head Injury Criteria

head injury criteria testing ( Determination of critical fall height – DIN EN 1177)

Sampeling Preparation

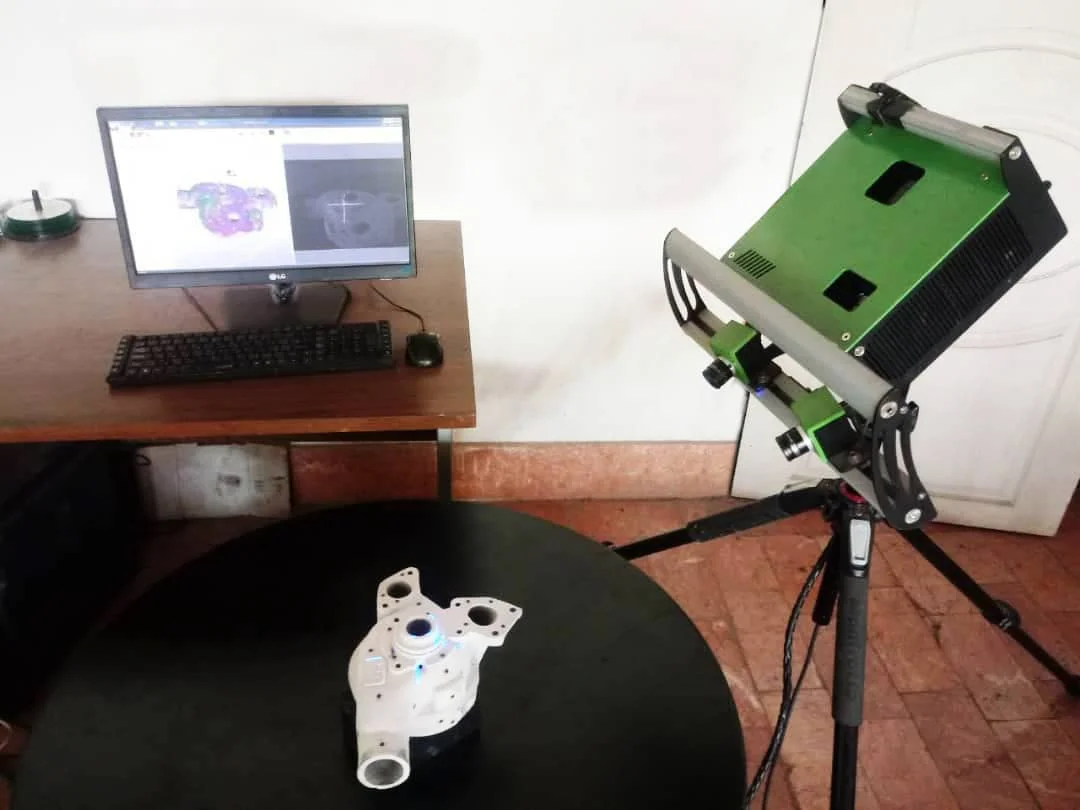

3D Scan

3D scanning of industrial and non-industrial parts and all parts that need redesign and 3D modeling, from small to large parts, is done with high accuracy and excellent quality. The output format of the 3D model is STL,STEP,… which most modeling software supports.

3D scanner and shape surface CAD

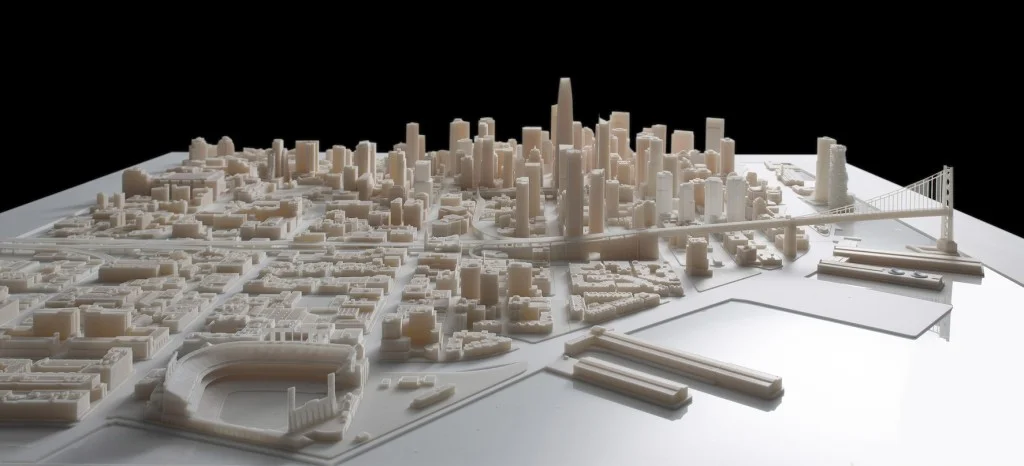

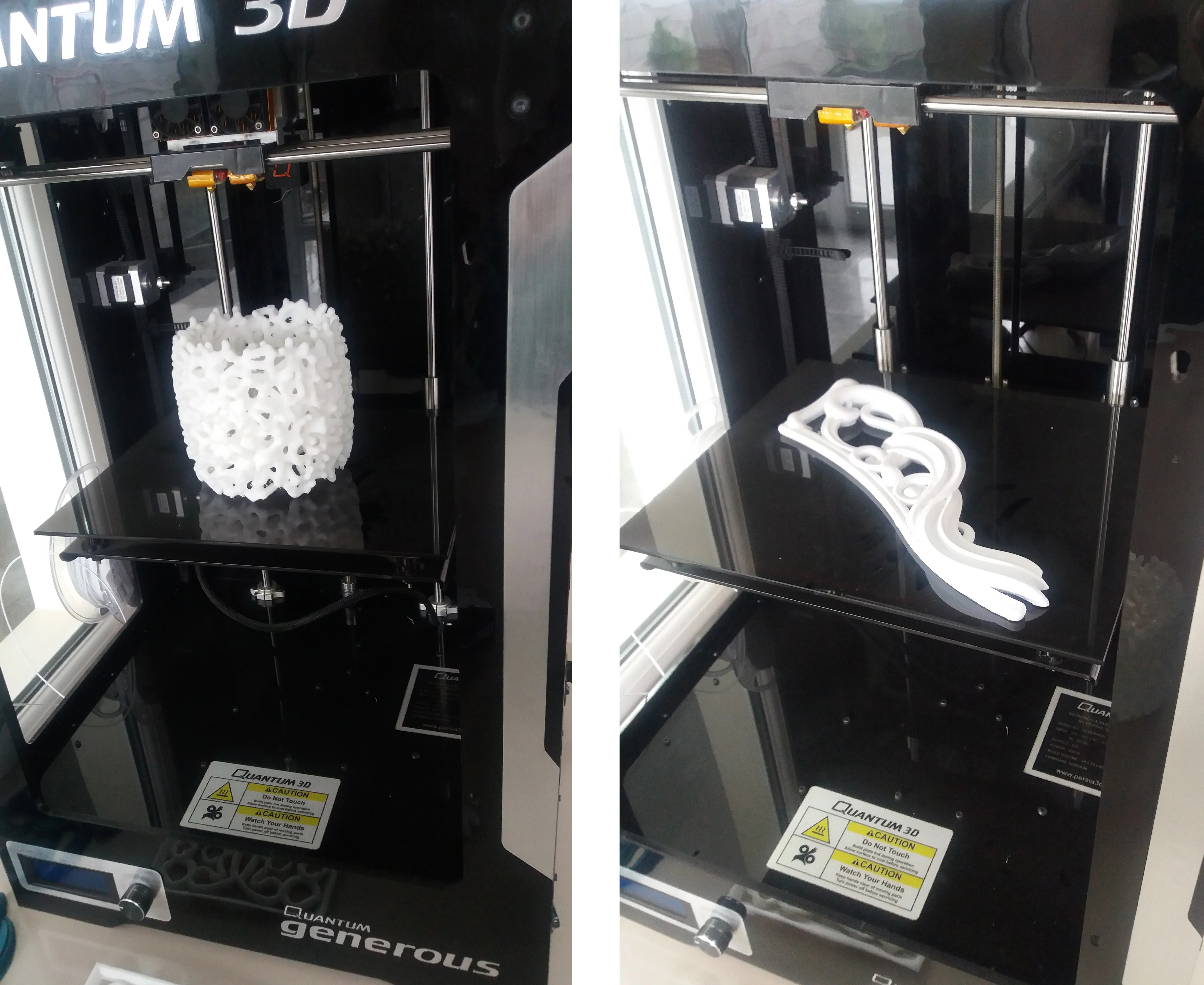

3D Print

3D printing technology is developing day by day. 3D printing is the process of making a 3D model of an object, which can be used to see its actual size and shape.

You’ve probably heard of 3D printers. Printers that print in three dimensions instead of two dimensions. Instead of printing ink on paper, 3D printers print a layer of plastic filament.

When these slices are placed directly on top of each other, incredibly complex designs can be made. From complex industrial parts to artistic models and…

When these slices are placed directly on top of each other, incredibly complex designs can be made. From complex industrial parts to artistic models and…